Easy operation

Okada breakers are designed to be the best match to the appropriate class of carrier. Nitrogen gas in the top of the piston provides a cushioning effect during the piston ascending stroke, minimizing vibration, which in turn reduces operator fatigue and wear and tear on the equipment.

Enhanced Durability and Longer Life

The square-shaped main body is created using a special alloy and subjected to advanced heat treatment processing, making the hammer body extremely durable. In addition, Okada hammers use fewer parts than competing brands of hydraulic breakers, so there is far less chance of problems developing. New special alloy steels and an advanced heat treatment system enhance main component durability. Medium and heavy class TOP series breakers are compatible with auto lube systems. By adding greasing points, both the shank bushing and front cap bushing are lubricated individually, resulting in longer service life.

Stringent Quality Control and Testing

From material selection and machining to hardening and final assembly, every step of production is controlled by an exhaustive quality control system. To ensure the absolute best quality possible, each unit is fully tested in a specially equipped room dedicated to performance inspection.

| IMPACT ENERGY CLASS | FT-LB |

| JOULES | |

| OPERATING WEIGHT | LBS |

| KG | |

| OIL FLOW | GPM |

| LPM | |

| FREQUENCY | BPM L-Mode |

| BPM S-Mode | |

| OPERATING PRESSURE | PSI |

| BAR | |

| MECHANICAL ENERGY | HP |

| KW | |

| MECHANICAL ENERGY AVG. | HP |

| KW | |

| UNIT WORKING LENGTH | INCHES |

| CM | |

| TOOL DIAMETER | INCHES |

| MM | |

| TOOL WORKING LENGTH | INCHES |

| MM | |

| CARRIER WEIGHT RANGE | 1000 LBS. |

| M TON | |

| TOP800 | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 15,000 |

| JOULES | 20,340 | |

| OPERATING WEIGHT | LBS | 12,350 |

| KG | 5601 | |

| OIL FLOW | GPM | 100-127 |

| LPM | 299-480 | |

| FREQUENCY | BPM L-Mode | 260-340 |

| - | ||

| OPERATING PRESSURE | PSI | 1990-2620 |

| BAR | 137-180 | |

| MECHANICAL ENERGY | HP | 108-182 |

| KW | 80-135 | |

| MECHANICAL ENERGY AVG. | HP | 145 |

| KW | 108 | |

| UNIT WORKING LENGTH | INCHES | 160 |

| CM | 406 | |

| TOOL DIAMETER | INCHES | 7.4 |

| MM | 188 | |

| TOOL WORKING LENGTH | INCHES | 40.5 |

| MM | 1029 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 110-220 |

| M TON | 50-100 | |

| TOP205J | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 4000 |

| JOULES | 5424 | |

| OPERATING WEIGHT | LBS | 4120 |

| KG | 1868 | |

| OIL FLOW | GPM | 36-53 |

| LPM | 136-200 | |

| FREQUENCY | BPM L-Mode | 370-430 |

| BPM S-Mode | 500-560 | |

| OPERATING PRESSURE | PSI | 2030-2620 |

| BAR | 140-180 | |

| MECHANICAL ENERGY | HP | 60-95 |

| KW | 45-71 | |

| MECHANICAL ENERGY AVG. | HP | 78 |

| KW | 58 | |

| UNIT WORKING LENGTH | INCHES | 103 |

| CM | 262 | |

| TOOL DIAMETER | INCHES | 5.3 |

| MM | 135 | |

| TOOL WORKING LENGTH | INCHES | 27.5 |

| MM | 699 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 40-60 |

| M TON | 18-27 | |

| TOP270B | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 5500 |

| JOULES | 7458 | |

| OPERATING WEIGHT | LBS | 5380 |

| KG | 2440 | |

| OIL FLOW | GPM | 47-63 |

| LPM | 178-238 | |

| FREQUENCY | BPM L-Mode | 400-500 |

| BPM S-Mode | 600-700 | |

| OPERATING PRESSURE | PSI | 2030-2465 |

| BAR | 140-170 | |

| MECHANICAL ENERGY | HP | 60-105 |

| KW | 45-78 | |

| MECHANICAL ENERGY AVG. | HP | 82.5 |

| KW | 62 | |

| UNIT WORKING LENGTH | INCHES | 123 |

| CM | 312 | |

| TOOL DIAMETER | INCHES | 5.5 |

| MM | 140 | |

| TOOL WORKING LENGTH | INCHES | 28.7 |

| MM | 730 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 44-66 |

| M TON | 20-30 | |

| TOP300J | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 7500 |

| JOULES | 10,170 | |

| OPERATING WEIGHT | LBS | 5952 |

| KG | 2700 | |

| OIL FLOW | GPM | 47-63 |

| LPM | 178-239 | |

| FREQUENCY | BPM L-Mode | 370-420 |

| - | ||

| OPERATING PRESSURE | PSI | 2320-2610 |

| BAR | 160-180 | |

| MECHANICAL ENERGY | HP | 66-113 |

| KW | 49-84 | |

| MECHANICAL ENERGY AVG. | HP | 89.5 |

| KW | 67 | |

| UNIT WORKING LENGTH | INCHES | 114 |

| CM | 290 | |

| TOOL DIAMETER | INCHES | 5.9 |

| MM | 150 | |

| TOOL WORKING LENGTH | INCHES | 32.5 |

| MM | 826 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 53-79 |

| M TON | 24-36 | |

| TOP400J | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 12,000 |

| JOULES | 16,272 | |

| OPERATING WEIGHT | LBS | 9350 |

| KG | 4240 | |

| OIL FLOW | GPM | 74-90 |

| LPM | 280-340 | |

| FREQUENCY | BPM L-Mode | 320-400 |

| - | ||

| OPERATING PRESSURE | PSI | 2320-2630 |

| BAR | 160-180 | |

| MECHANICAL ENERGY | HP | 103-167 |

| KW | 77-125 | |

| MECHANICAL ENERGY AVG. | HP | 135 |

| KW | 101 | |

| UNIT WORKING LENGTH | INCHES | 145 |

| CM | 368 | |

| TOOL DIAMETER | INCHES | 6.7 |

| MM | 170 | |

| TOOL WORKING LENGTH | INCHES | 36.8 |

| MM | 935 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 88-132 |

| M TON | 40-60 | |

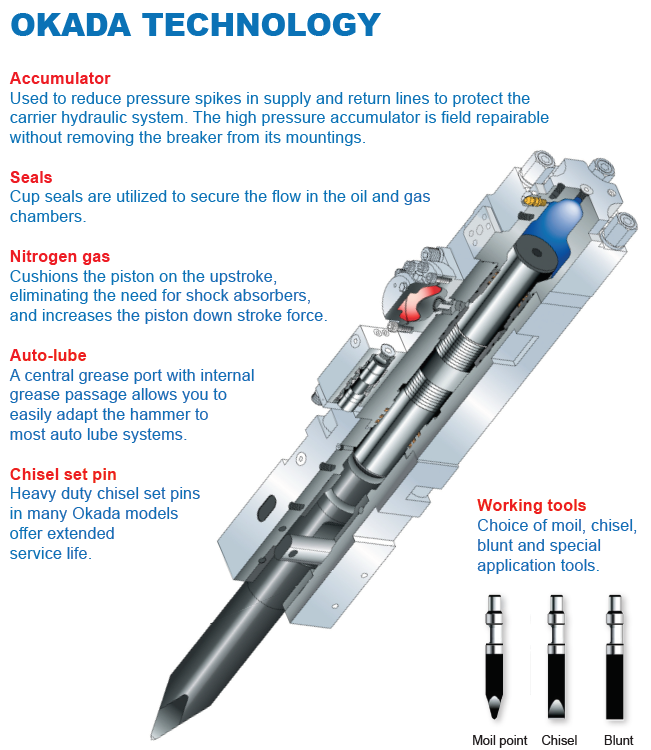

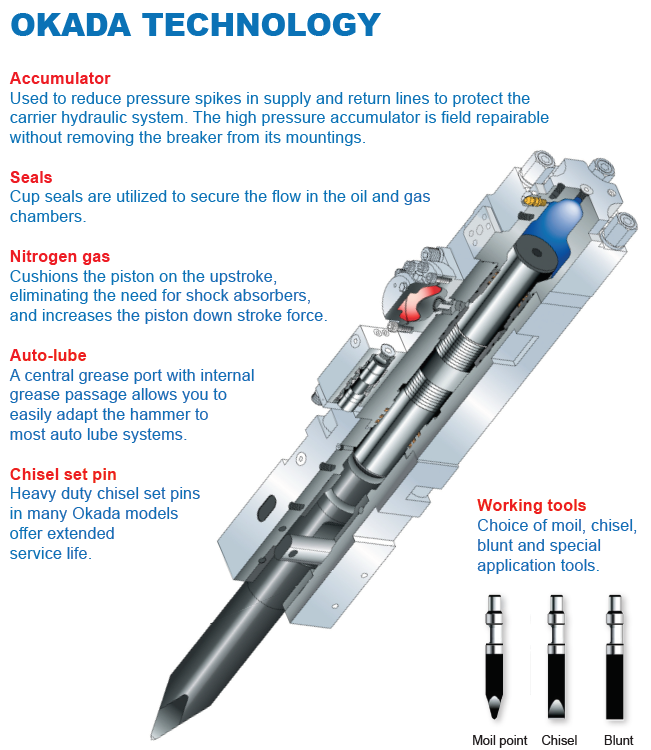

Used to reduce pressure spikes in supply and return lines to protect the carrier hydraulic system. The high pressure accumulator is field repairable without removing the breaker from its mountings. Breakers under 4000 lbs. do not require accumulators.

Cup seals are utilized to secure the flow in the oil and gas chambers.

Cushions piston on the upstroke, eliminating the need for shock absorbers. Increases the piston down stroke force.

A central grease port with internal grease passage allows you to easily adapt the hammer to most Auto Lube systems.

Choice of moil, chisel, blunt and special application tools.

Travels through one machined piece (no misalignment). The long stroke design reduces shock loads and vibration, which can cause operator fatigue and machine stress. Okada breakers have the highest tolerance to high operational back pressures available without negative operational effects.

Heavy dual chisel set pins in many Okada models offer extended service life.