Precision machining processes and strict Okada quality control are used to produce all main breaker components. There is no need for complete assembly replacements and the use of high precision parts mean economical, labor-saving rebuilds of your Okada breaker.

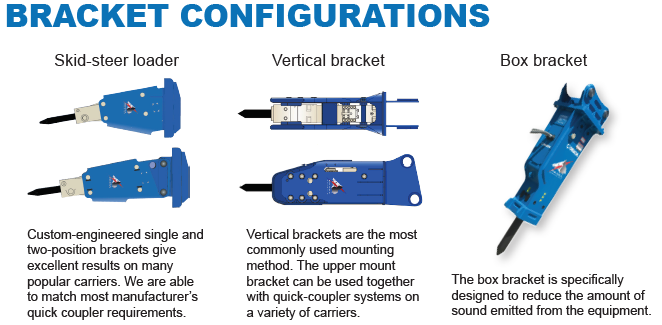

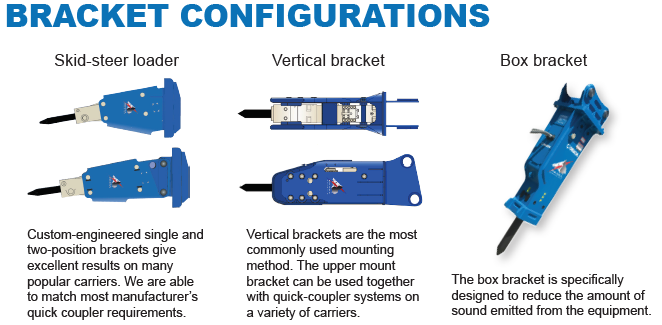

Breaker brackets are made of heavy gauge high tensile steel plates and are designed to give maximum protection to the breaker body and dissipate heat while making it easier to access the equipment during daily maintenance inspection.

Okada bushing designs, a special heat treatment process and individually lubricated bushings enhance the service life of wear parts

| IMPACT ENERGY CLASS | FT-LB |

| JOULES | |

| OPERATING WEIGHT | LBS |

| KG | |

| OIL FLOW | GPM |

| LPM | |

| FREQUENCY | BPM L-Mode |

| BPM S-Mode | |

| OPERATING PRESSURE | PSI |

| BAR | |

| MECHANICAL ENERGY | HP |

| KW | |

| MECHANICAL ENERGY AVG. | HP |

| KW | |

| UNIT WORKING LENGTH | INCHES |

| CM | |

| TOOL DIAMETER | INCHES |

| MM | |

| TOOL WORKING LENGTH | INCHES |

| MM | |

| CARRIER WEIGHT RANGE | 1000 LBS. |

| M TON | |

| TOP150 | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 3000 |

| JOULES | 4068 | |

| OPERATING WEIGHT | LBS | 3000 |

| KG | 1361 | |

| OIL FLOW | GPM | 31-41 |

| LPM | 115-155 | |

| FREQUENCY | BPM L-Mode | 600-750 |

| - | ||

| OPERATING PRESSURE | PSI | 2030-2620 |

| BAR | 140-180 | |

| MECHANICAL ENERGY | HP | 42-63 |

| KW | 31-47 | |

| MECHANICAL ENERGY AVG. | HP | 52.5 |

| KW | 39 | |

| UNIT WORKING LENGTH | INCHES | 94 |

| CM | 239 | |

| TOOL DIAMETER | INCHES | 4.8 |

| MM | 122 | |

| TOOL WORKING LENGTH | INCHES | 24 |

| MM | 610 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 28-42 |

| M TON | 13-19 | |

| TOP60CX | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 1500 |

| JOULES | 1695 | |

| OPERATING WEIGHT | LBS | 1190 |

| KG | 540 | |

| OIL FLOW | GPM | 17-23 |

| LPM | 64-87 | |

| FREQUENCY | BPM L-Mode | 730-970 |

| - | ||

| OPERATING PRESSURE | PSI | 1740-2320 |

| BAR | 120-160 | |

| MECHANICAL ENERGY | HP | 20-37 |

| KW | 15-27 | |

| MECHANICAL ENERGY AVG. | HP | 28.5 |

| KW | 21 | |

| UNIT WORKING LENGTH | INCHES | 81 |

| CM | 206 | |

| TOOL DIAMETER | INCHES | 3.3 |

| MM | 84 | |

| TOOL WORKING LENGTH | INCHES | 21.2 |

| MM | 538 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 12-20 |

| M TON | 5-9 | |

| TOP90 | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 2000 |

| JOULES | 2712 | |

| OPERATING WEIGHT | LBS | 1450 |

| KG | 658 | |

| OIL FLOW | GPM | 22-31 |

| LPM | 83-117 | |

| FREQUENCY | BPM L-Mode | 550-850 |

| - | ||

| OPERATING PRESSURE | PSI | 2030-2620 |

| BAR | 140-180 | |

| MECHANICAL ENERGY | HP | 30-56 |

| KW | 23-42 | |

| MECHANICAL ENERGY AVG. | HP | 43 |

| KW | 32 | |

| UNIT WORKING LENGTH | INCHES | 84 |

| CM | 213 | |

| TOOL DIAMETER | INCHES | 3.9 |

| MM | 99 | |

| TOOL WORKING LENGTH | INCHES | 21.9 |

| MM | 556 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 15-26 |

| M TON | 7-12 | |

| TOP100A | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 2500 |

| JOULES | 3390 | |

| OPERATING WEIGHT | LBS | 2440 |

| KG | 1107 | |

| OIL FLOW | GPM | 31-41 |

| LPM | 115-155 | |

| FREQUENCY | BPM L-Mode | 550-710 |

| - | ||

| OPERATING PRESSURE | PSI | 2030-2620 |

| BAR | 140-180 | |

| MECHANICAL ENERGY | HP | 40-63 |

| KW | 30-47 | |

| MECHANICAL ENERGY AVG. | HP | 51.5 |

| KW | 38 | |

| UNIT WORKING LENGTH | INCHES | 81 |

| CM | 206 | |

| TOOL DIAMETER | INCHES | 4.3 |

| MM | 109 | |

| TOOL WORKING LENGTH | INCHES | 23.4 |

| MM | 594 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 22-42 |

| M TON | 10-18 | |

| TOP205J | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 4000 |

| JOULES | 5424 | |

| OPERATING WEIGHT | LBS | 4120 |

| KG | 1868 | |

| OIL FLOW | GPM | 36-53 |

| LPM | 136-200 | |

| FREQUENCY | BPM L-Mode | 370-430 |

| BPM S-Mode | 500-560 | |

| OPERATING PRESSURE | PSI | 2030-2620 |

| BAR | 140-180 | |

| MECHANICAL ENERGY | HP | 60-95 |

| KW | 45-71 | |

| MECHANICAL ENERGY AVG. | HP | 78 |

| KW | 58 | |

| UNIT WORKING LENGTH | INCHES | 103 |

| CM | 262 | |

| TOOL DIAMETER | INCHES | 5.3 |

| MM | 135 | |

| TOOL WORKING LENGTH | INCHES | 27.5 |

| MM | 699 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 40-60 |

| M TON | 18-27 | |

| TOP270B | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 5500 |

| JOULES | 7458 | |

| OPERATING WEIGHT | LBS | 5380 |

| KG | 2440 | |

| OIL FLOW | GPM | 47-63 |

| LPM | 178-238 | |

| FREQUENCY | BPM L-Mode | 400-500 |

| BPM S-Mode | 600-700 | |

| OPERATING PRESSURE | PSI | 2030-2465 |

| BAR | 140-170 | |

| MECHANICAL ENERGY | HP | 60-105 |

| KW | 45-78 | |

| MECHANICAL ENERGY AVG. | HP | 82.5 |

| KW | 62 | |

| UNIT WORKING LENGTH | INCHES | 123 |

| CM | 312 | |

| TOOL DIAMETER | INCHES | 5.5 |

| MM | 140 | |

| TOOL WORKING LENGTH | INCHES | 28.7 |

| MM | 730 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 44-66 |

| M TON | 20-30 | |

| TOP300J | ||

|---|---|---|

| IMPACT ENERGY CLASS | FT-LB | 7500 |

| JOULES | 10,170 | |

| OPERATING WEIGHT | LBS | 5952 |

| KG | 2700 | |

| OIL FLOW | GPM | 47-63 |

| LPM | 178-239 | |

| FREQUENCY | BPM L-Mode | 370-420 |

| - | ||

| OPERATING PRESSURE | PSI | 2320-2610 |

| BAR | 160-180 | |

| MECHANICAL ENERGY | HP | 66-113 |

| KW | 49-84 | |

| MECHANICAL ENERGY AVG. | HP | 89.5 |

| KW | 67 | |

| UNIT WORKING LENGTH | INCHES | 114 |

| CM | 290 | |

| TOOL DIAMETER | INCHES | 5.9 |

| MM | 150 | |

| TOOL WORKING LENGTH | INCHES | 32.5 |

| MM | 826 | |

| CARRIER WEIGHT RANGE | 1000 LBS. | 53-79 |

| M TON | 24-36 | |

Used to reduce pressure spikes in supply and return lines to protect the carrier hydraulic system. The high pressure accumulator is field repairable without removing the breaker from its mountings. Breakers under 4000 lbs. do not require accumulators.

Cup seals are utilized to secure the flow in the oil and gas chambers.

Cushions piston on the upstroke, eliminating the need for shock absorbers. Increases the piston down stroke force.

A central grease port with internal grease passage allows you to easily adapt the hammer to most Auto Lube systems.

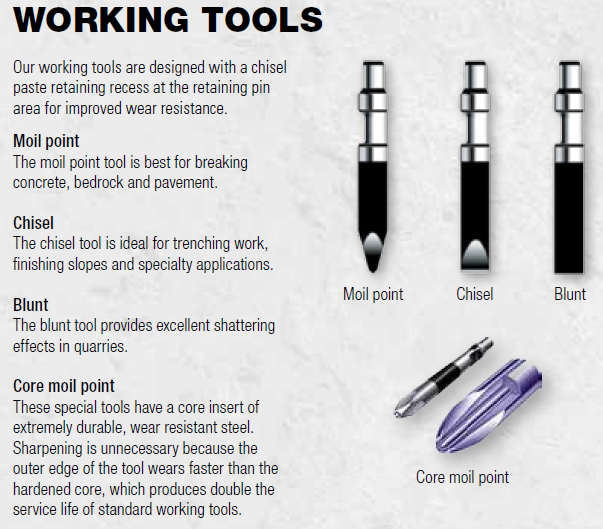

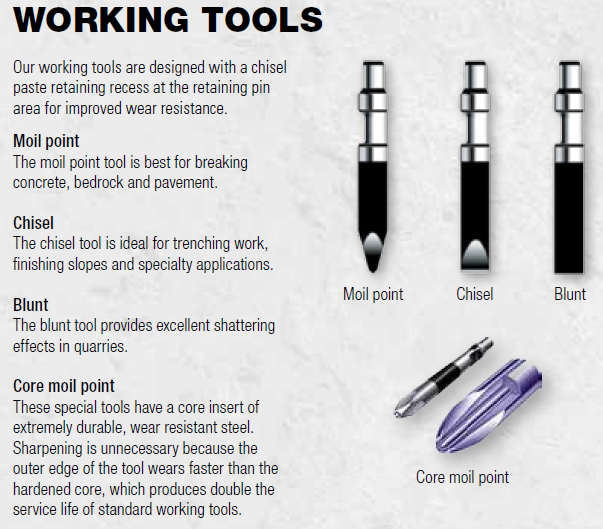

Choice of moil, chisel, blunt and special application tools.

Travels through one machined piece (no misalignment). The long stroke design reduces shock loads and vibration, which can cause operator fatigue and machine stress. Okada breakers have the highest tolerance to high operational back pressures available without negative operational effects.

Heavy dual chisel set pins in many Okada models offer extended service life.